When purchasing anchor chains, ropes, and anchors, selecting the right lengths and deploying them correctly is critical for vessel safety and stability. This guide simplifies the process, ensuring you make informed decisions based on water depth, weather, and currents.

Step 1: Calculating Total Anchor Chain & Rope Length (A)

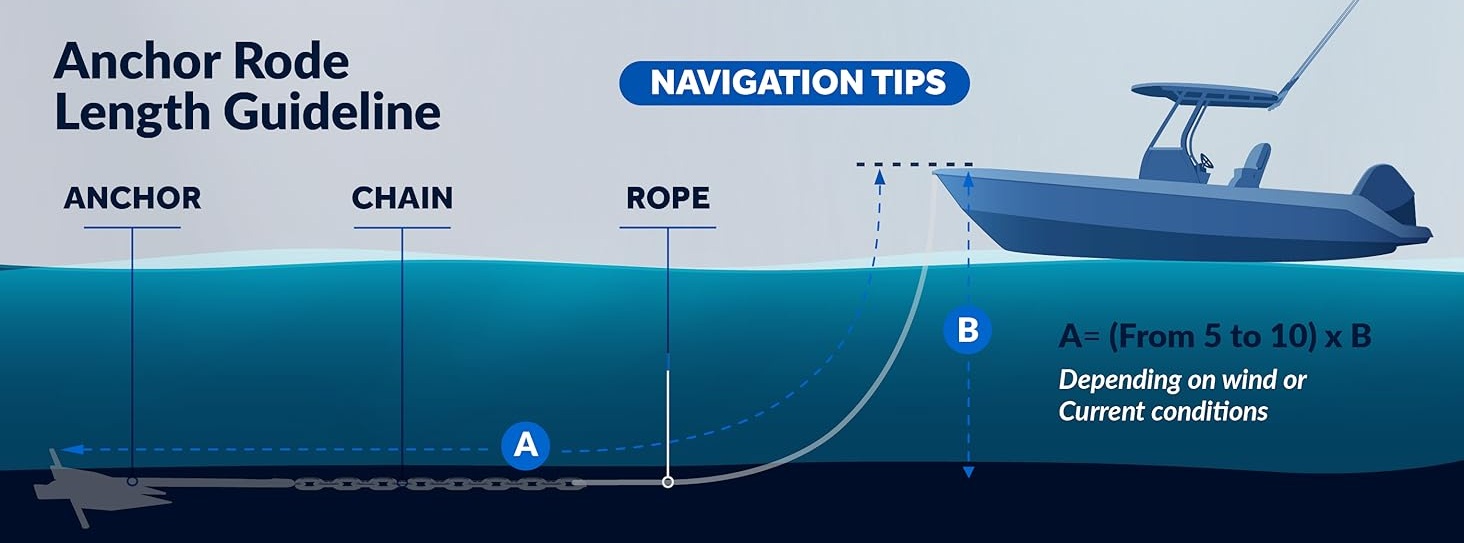

Your anchor system’s total length (chain + rope) depends on the water depth from your deck to the seabed (B). Use this formula:

A = (5 to 10) × B

– B: Vertical distance from deck to seabed (as shown in the diagram).

– 5–10 multiplier: Adjust based on conditions:

– Calm weather (light winds, slow currents): Use 5×B.

– Moderate conditions: Opt for 7×B.

– Stormy weather or strong currents: Extend to 10×B.

Why this range? A longer scope (A) improves holding power by ensuring the anchor lies flat on the seabed. Too short, and your vessel risks dragging.

Step 2: Deploying the Anchor System Correctly

Once you’ve calculated A, follow these best practices:

1. Check depth (B): Use a depth sounder to measure the water depth.

2. Factor in tide changes: If tides rise, increase B accordingly.

3. Deploy gradually: Release the chain/rope slowly while reversing the boat to lay it straight.

4. Set the anchor: Apply gentle reverse thrust to embed the anchor securely.

Key Factors Affecting Your Choice

1. Wind & Currents: Higher forces require longer scopes.

2. Seabed Type: Mud/sand holds better than rocks; adjust length as needed.

3. Vessel Size: Larger boats need heavier chains and longer scopes.

Pro Tip: Always inspect chains and ropes for wear before deployment. Quality gear ensures reliability in harsh conditions.

Need Durable Anchoring Solutions?

Explore our premium marine-grade anchor chains, UV-resistant ropes, and high-holding anchors designed for all conditions. Shop Now!

By optimizing your anchor scope and using quality equipment, you ensure safety and peace of mind on the water. For personalized advice, contact our experts.